Shorten your line, save money, add safety

Accumulating costs associated with fitting SnapXit™ kits on a bus is an eye-opener. Those who want to shorten time on the line save money while adding safety equipment, let’s start with the ubiquitous “toffee” hammer and its combined costs.

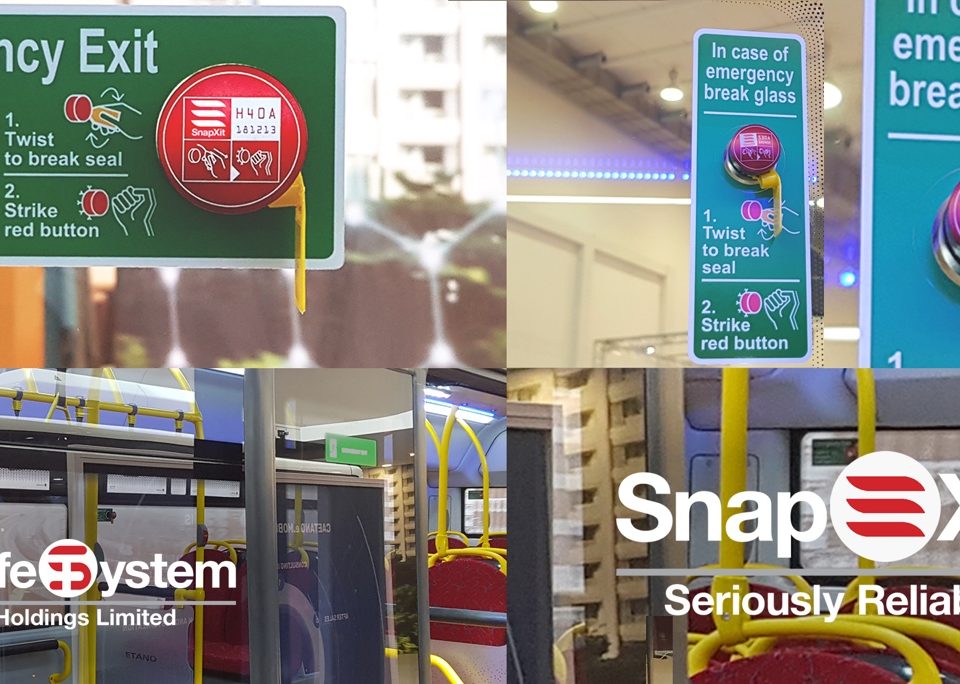

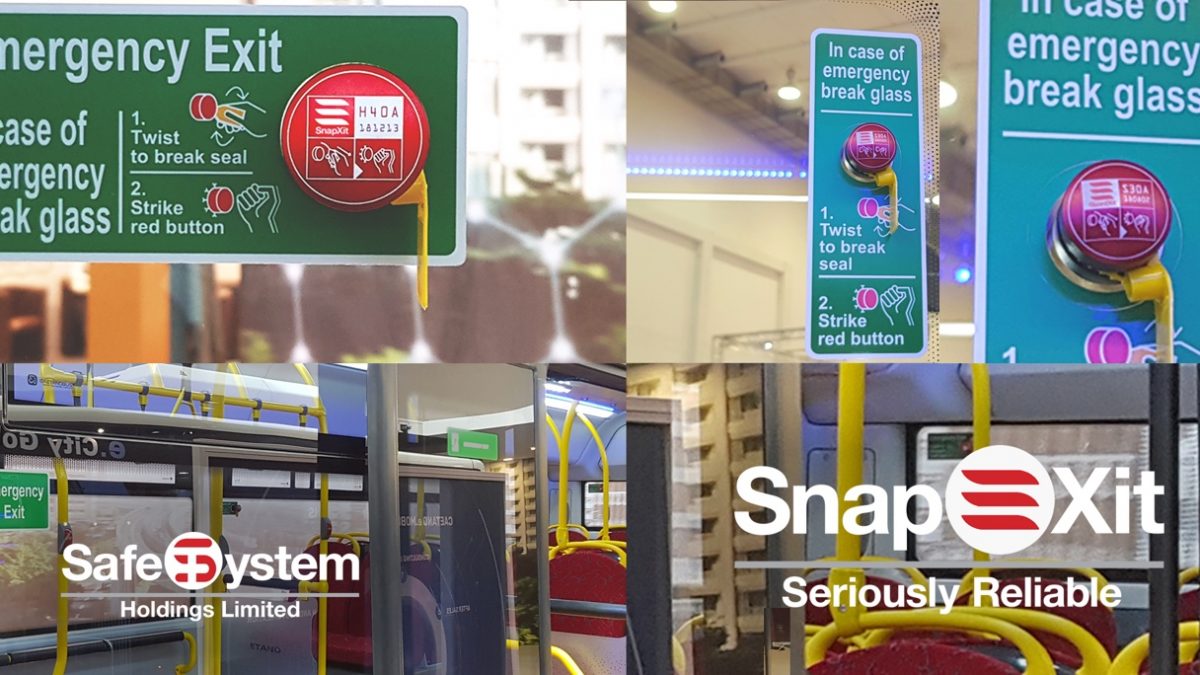

At some point on your production line, you will find one or two skilled technicians fitting emergency exit assemblies. They’d need the hammer and the bracket, and it’s return cable, rivets and screws, power tooling, possibly a cabinet, and electronics for alarms and emergency lighting. Each hammer fitting would take perhaps an hour to complete, including adding the instructions information and exit stickers. The basic accumulated material and skills costs are considerable even before you include the production line’s floor space.

To fit a SnapXit™ kit, you need some IPA and paper towelling, a squeegee, and a trainee or unskilled technician. An entire vehicle can be fitted out in 10 minutes, in the parking lot, just before inspection.

No production line station, no power tooling, no expensive skilled labour.